- Technical specifications of existing modelsUnique Design and High Reliability

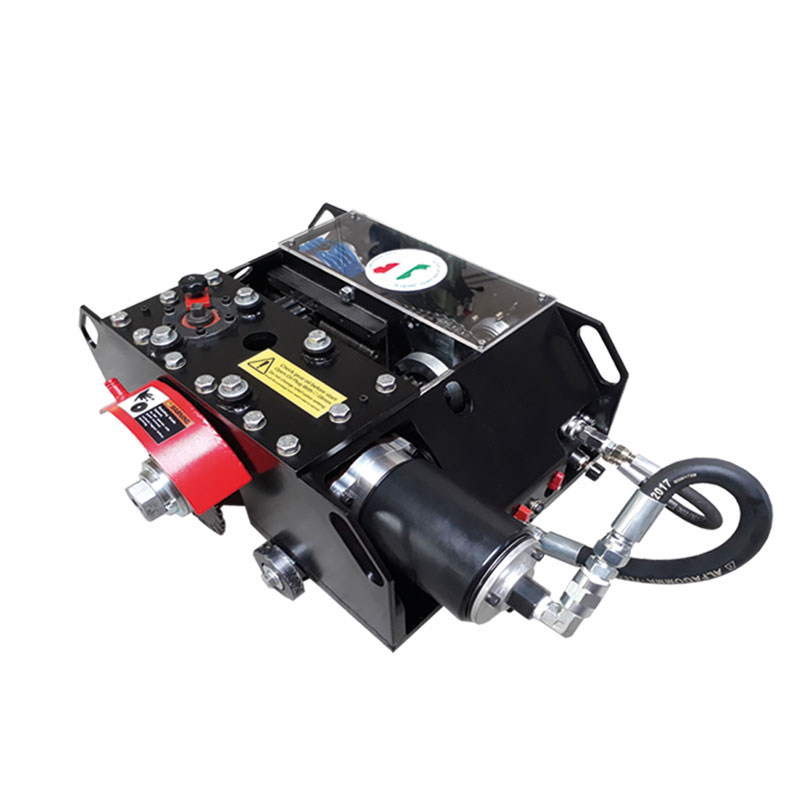

This machine was designed and produced in IRAN by Part Arya Company,since early 2002 . High quality and reliability of the products fulfills all the customers requirements.

- Cold cutting and beveling simultaneously on all machinable pipe materials. (Ready for welding).

- Pipe sizes from 6” to 72” O.D.

- Ability to Cut & Bevel large tanks and vessels up to 10 meters in diameter.

- Portable and ability to work in fields, workshops onshore and offshore operations.

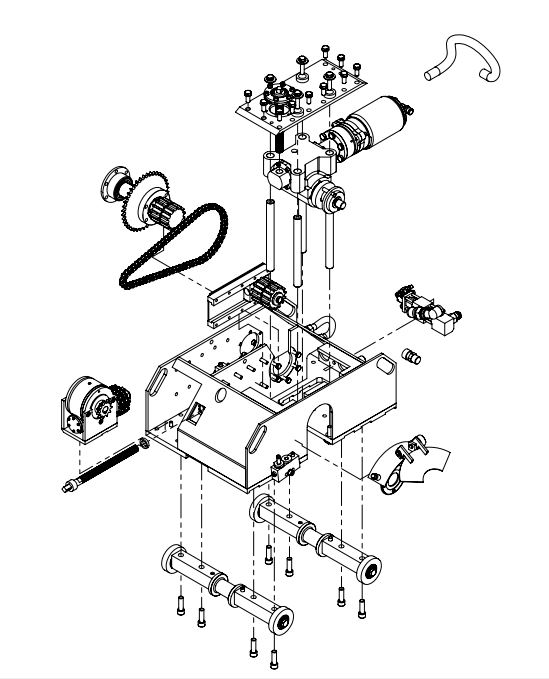

- Secured by its own tension chain, propels itself around the pipe, machining as it travels around the work piece.

- Easy and fast set up (Max 10 min).

- Pipe end with smooth machined finish.

- Cutting speed of 1 inch of Dia./Min for standard wall pipe thickness. (½”)

- Typical tolerances of 1.5 mm closure.

- By using an optional guide track and wheels, the accuracy of 0.12 mm can be maintained even in zero visibility.

- Operation in both vertical and horizontal pipes.

- Operation in a mud or under water.

- Long life operation.

- Ability to cut & Bevel simultaneously materials such as carbon steel, ductile iron, cast iron and most alloys.

- Well suited for use in explosive conditions such as natural gas, crude oil products and fuel lines.

- Available in two kinds of pneumatic and hydraulic drives.

- Wide Range Application : This machine is produced in pneumatic or hydraulic models, can be used in almost all industries such as construction & maintenance of all pipe line sizes in the fields of oil, gas, petrochemical and water supply, factories and workshops production lines, refineries,marine industries and etc…

- Fast, Accurate and Safe cutting anywhere : This machine is portable, capable of cold cutting and beveling simultaneously, vertical or horizontal pipes of all machinable materials, sizes from 6” to 72” O.D. even in worst conditions such as explosive and under water. This machine travels itself around the pipe secured by its own tension chain, machining as it travels. This machine can also cut tanks and large vessels.

- Standard Equipment:

Operational manual and isometric parts lists, Chain connecting pins, Full operating tools, Torque meter wrench, Crane cable, 5 meters H.P. hose with quick change connections,in-line Air Lubricator, Full set of consumable oils. - Other Equipment:

Tension chain sections from 6” to 72”, Spray mist cooling system, Guide track and wheels, Cutter blades.